INOXCVA values the interests of all stakeholders and ensures complete safety & health of all employees, customers, suppliers and connected communities during the unprecedented COVID-19 pandemic.

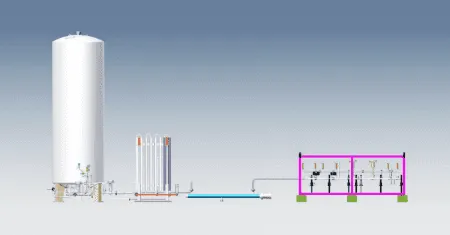

Designated under Essential Services by the Government, under relevant approvals and strict adherence to safety protocols & notifications by the authorities & health specialists, INOXCVA resumed its manufacturing operations and ensured consistent on-time supply of critical Liquid Medical Oxygen Storage Vaporisation and Distribution equipment to Hospitals and Emergency make-shift Medical facilities set-up in India and overseas.

Our works team are relentlessly ensuring maximum production despite resource constraints, our Sales Teams have maintained active connected with all customers by Tele/Video calling & conferencing, on-line events, apart from emails & social media platform, and providing them the confidence & updates on delivery commitments. Our customer services teams fearlessly travel to critical medical installation project sites to install & commission LOX storage systems ensuring un-interrupted operations.

Team INOXCVA firmly joined hands with the medical fraternity in the relentless fight against COVID-19, and maintained our global operations to serve the needs of our customers, against all odds.

We are fervently remain committed to maintaining quality of our products and providing world class customer services to our customers within a safe & protected work environment.

-april-2020.webp)