2015-2025 — Warm Line (W Group)

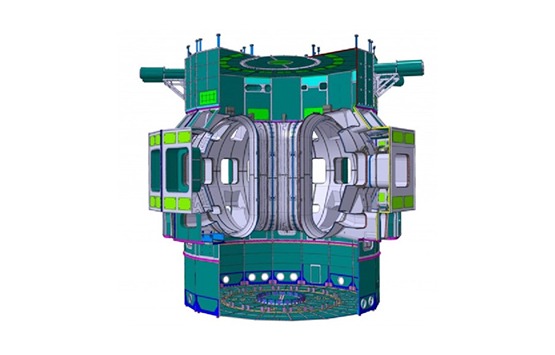

Between 2015 and 2025, INOXCVA delivered the design, manufacturing, supply, installation, and acceptance testing of the ITER Warm Line (W Group), a 6 km network engineered to transport gaseous helium and nitrogen under varied pressure, temperature, and mass-flow conditions and an oil filter to filter out oil contamination from helium gas before it is vented to the atmosphere. This sophisticated system forms a critical link between ITER’s cryogenic infrastructure and its multiple subsystems, ensuring uninterrupted distribution of cryogens to key applications.

Designed, manufactured, and tested in full compliance with EN 13480 standards, French nuclear safety regulations, and EN 12300 (+A1)/ISO 23208 cleaning protocols, the Warm Line integrates several essential routes, including distribution lines, current lead lines, purge lines, high-pressure helium supply to the cryo-pump regeneration box, return lines from cryo-pumps, LHe plant connections, 80 K loop circuits, nitrogen plant lines, and regeneration lines. Collectively, these components ensure efficient cryogen circulation and return, ensuring ITER’s precision-driven cryogenic ecosystem.